Overview

Our sharpening service will provide a good serviceable edge on the blade. The result is typically “very sharp” with a small secondary bevel and a bit of an “apple seed” profile. The resulting edge is somewhat dependent on the particular blade. Some blades will take and hold sharper edges than others and the thickness of the blade will determine how wide the bevel will need to be. We adjust the angle of the edge to suit the specific blade and attempt to get as close to a bevel-less edge as possible without marring the surface of the blade.

The Sharpening Process

The sharpening service is done with a belt sander. The process involves many passes with sanding belts of various grits. The blades are rested between passes to prevent them from becoming hot and damaging their temper. By default we will sharpen as much of the blade as possible including any false edges if appropriate. If you have a different preference, feel free to make that request in the special instructions at check out. We can sharpen only the last half or third of an edge, for example. Our sword sharpening expert has personally sharpened several thousand swords at this point, so will provide you with a professional service.

What the Service is Not

The resulting edge will be “sword sharp” not razor sharp. Our goal is to provide you with a usable edge for cutting practice that will hold up to some use and not require constant re-sharpening. In other words, we intend to provide you with a serviceable weapon, not a personal grooming implement. The service will not provide a completely bevel-less edge. To create that type of edge will necessarily scratch up the blade surface and we lack the machinery and time to provide a full re-polishing of a blade’s surface. A service of that nature would be significantly more expensive as a great deal more time would be required. We do not offer this type of service at this time.

Disclaimer

We make no guarantee that the resulting edge will meet with your expectations. Every blade is different and some will take and hold a sharper edge than others, due to the blade material, heat treatment or geometry. Some customers can also have incorrect assumptions about sword sharpness and improper expectations as a result. All we can say for sure is that the resulting edge will be sharper than the default edge, in most cases, significantly so. We can not provide any refunds for the service once it has been completed, so consider it to be provided “as is”. That being said, if you are unhappy with the product for any reason, we do still allow you to return the item for a full refund, including the sharpening costs under our normal return policy. This does not apply to special sharpening requests, for example if we sharpen something specially for you that does not normally list that option on our site. The vast majority of our customers are happy with the results of the service, so as long as you keep the above mentioned in mind, we are confident you will be pleased with the results as well.

James Whitworth –

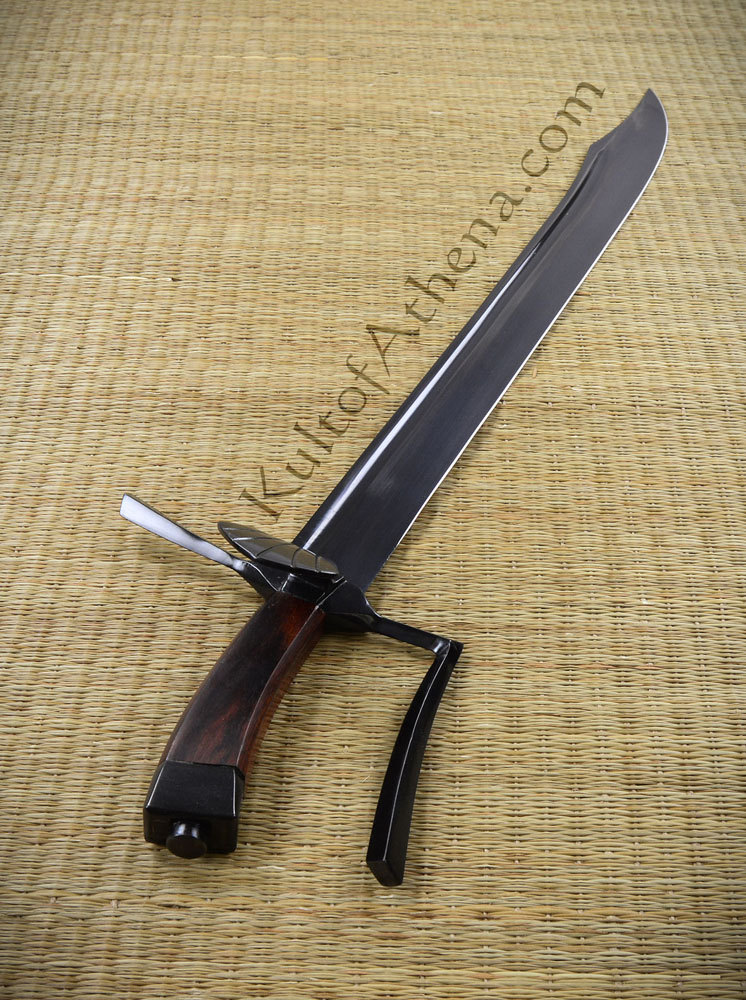

Great handling but not accurate. Overall this is a awesome sword. It’s lighter than even my Hanwei oxtail dao. It’s also solidly constructed. My biggest gripe is that it’s not technically a messer because it’s not a true full tang. If it was built like a knife with a full tang with wood scales it would be much more accurate and probably much better built. My biggest issue with many Cold Steel swords is that a lot of them have hidden tangs that are glued in place. As a result you can’t really see how big the tang is or how it’s constructed. Despite that this is very solid and of course it’s low maintenance being blued. Plus it’s hard to beat the price.

Raul Cenan –

I got this sword a little while ago. I do like the design and handling a lot, however I wasn’t quite happy with the grip shape (tapers together too much at the guard) so I wanted to make my own custom grip. Sounds easy enough, the tang is threaded so I unscrewed the nut holding it in place then proceeded to use a rubber mallet to knock on the guard to get the grip off. Firstly, the grip is on pretty tight so that’s a good thing if you do not intend to mess/customize the sword. Everything was going good until I noticed that the knuckle-bow started to break at the 90 degrees “bend”. it basically turns out that the construction of the guard is in several steel core pieces which are surrounded by some softer cast metal (iron?) and the steel core pieces are not welded together so if exposed to repeated impact the outer casting will break. I did not hammer very hard on it, just enough to knock the grip loose but it was enough to break the guard. It’s really a shame as the design of the guard (visually) is quite nice but the construction method is questionable. As far as James’s worry about the tang goes: the tang is fairly burly with just a short piece of thread on the end and it appears that the threaded part is not welded on but a part of the actual tang that is threaded, so the blade and tang should be pretty strong. Again, it’s not a bad sword and looks good for the money but the knuckle-bow cannot take any impacts due to the construction. So if anybody wants to customize the grip: DON’T unless you want to break the knuckle-bow. I wonder if cold steel sell the guard as a separate piece? Right now I’m looking into repairing the broken knuckle bow with some silver solder… might be stronger than the original but it will ruin the finish… or I could make my own guard out of ONE PIECE of steel but that’s a lot of work. I also sharpened the false edge on mine and did some extensive sharpening compared to the factory edge. I will make a custom deer antler grip for it since I already took it apart.

Bottom line: it’s a good sword for the price if you don’t intend to mess with it but do not use the knuckle bow for any sort of impacts as it might break on you. I am not particularly sour at Cold Steel since I decided to mess with the product and it wasn’t very expensive, but for future reference the knuckle bow connection should be welded underneath the outer casting to make it an actual structural piece.

Robert E Malecek (verified owner) –

Good cutter, a few durability concerns.

I bought this sword for recreational cutting, big game (hog) dispatch, and sabrage. The sword looks good and came with a keen edge, but I’ve had a few problems I feel are worth mentioning.

When it first arrived I used it to cut a few boxes, a few bottles, and a a few 20-25 mm green Aspen shoots, but while it cut all of those cleanly and with authority, the Aspen shoots were enough to loosen the hilt on the blade. Attempting to tighten the hilt with the pommel nut caused the wooden grip to crack before the hilt tightened up (the hilt has stayed tight since I tightened the pommel nut and cracked the grip). I had intended to replace the grip material with bone or antler anyways, so I’m not heartbroken about the grip, but considering this sword’s reputation as a fearsome cutter on a budget, it should be mentioned in my review.

Second, the chape and throat doesn’t seem to have been debured before they finished the metal, and they are moderately sharp. But you didn’t buy this sword for the sheathe.

The edge has held up to the cutting that loosened the hilt and to all the cutting since then, including a test on fresh flesh and bone (the shanks of a roadkilled deer), until I used it for sabrage for the first time, whereupon it rolled the edge quite severely.

I’ll be able to re-profile the blade to have a more robust edge, but I’ve used knives with keener edges to sabre champagne before without damage (specifically a K-bar plain edge and a Buck 120) and I’m a little disappointed that I won’t be able to keep the very keen factory edge, and it’s admirable performance on the mixed targets I’ve so far subjected it to except (except the champagne bottle glass). Hopefully I’m able to find a profile that cuts aggressively but strengthens the edge enough to continue to use this sword for sabrage.