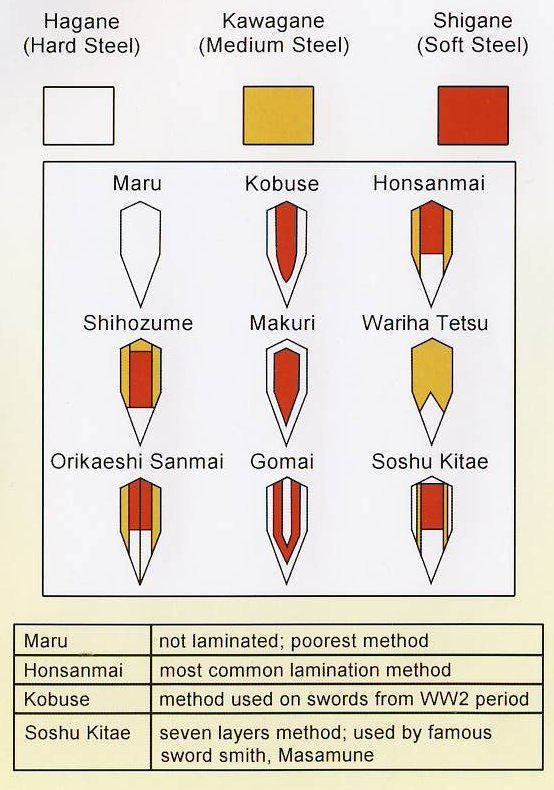

The Meiso katana is fitted with a Honsanmai style laminated blade that was crafted with 1095, 1060 and 1045 high carbon steel. This lamination forge-welded the blade to possess an edge of hard steel, with a jacket of medium-hard steel and a core of softer steel to give it a durable, shock-absorbing spine. The blade was also differentially-tempered with the traditional application of the clay method to further harden the edge and to give it the distinctive, wave-like hamon.

The tip was formed with a geometric yokote and a Chu-Kissaki tip. The sword has been lightened with a bo-hi groove to give it fine handling characteristics; as a side effect, this form also amplifies the Tachikaze sword wind – an audible whoosh or whistle made when the blade passes through the air. A skilled ear can discern the alignment of the blade by the pitch of this sound.

The Tsuba, Fuchi and Kashira fittings are iron and the habaki and seppa are brass. The tsuba is in the form of a humble, but dignified bamboo mat and the fuchi and kashira depict, in frozen iron, the waves of the sea. The carved wood tsuka grip has panels of inlaid rayskin; the black silk ito was wrapped with underlying hishigami triangles to both tighten the grip and give it traditional form. The Saya scabbard of wood is finished with a textured black lacquer finish and a knotted black Sageo cord. A cloth sword bag is included.

Honsanmai was one of the most common methods used for laminating Katana in Japans pre-industrial period. It is simpler than some of the more complex methods, such as Soshu Kitae, yet practical and effective. The blade has a core body of softer steel fitted between side panels of medium steel and an edge partition of hard steel. This form gives the blade a hard cutting edge that will cushion itself in the strike against the softer core with its shock absorbing properties. The sides of medium-hard steel resist damage to the body of the blade and effectively armor the core.

Laminations were a common method for forging katana because the swordsmith could make effective use of his steel blooms in a way that effectively hedged against the possibility of impurities or bad welds in the steel. Though a laminate is composed of welded sections, should significant damage occur to the blade the possibility of the damage being contained within its partition is increased due to a lamination. For example, a crack in the edge due to damage is less likely to continue through the core of the blade in a lamination and thus the blade could more durably hold together for its master until the aftermath of a battle or duel.

Laminated blades also had a substantial degree of durability due to the softer core being able to absorb force and resist breaking, unlike more brittle blades. The warrior wanted a blade that could keep a hard and vicious cutting edge, but the inherent brittleness of such a hard edge was countered by a thick flexing spine.

Due to the availability of excellent, pure steel and advanced methods to control tempering, the benefits of a well-crafted laminated katana are not significant when compared against a through-tempered, flexing mono-steel katana or a well-tempered differentially-hardened mono-steel katana.

A well-crafted laminate is still an excellent cutting sword and a thing of beauty and they are, in themselves, a showcase of the utilitarian artistry of the traditional Japanese swordsmith and his time-honed techniques. They capture a certain aura of the traditional Katana and its masterful smith that cannot be found in many other, more conveniently crafted Katana.

Matthew L. –

Beautiful katana I have to admit I was tired of waiting for another T10 model so I took a chance on this and im glad i did. This Katana was built right. The lamination is disable, Tsuka is tight, and the blade is perfectly balanced. It’s a light blade but is strong enough to cut through 3.5 in rolled paper with wood cores. The only things I didn’t care for is this type of sageo material it will fray too easy. Also the sword fits a little tight in the saya but more towards the tip of the blade so there is no way to adjust it without cutting it open. I would definitely buy this again