Overview

Our sharpening service will provide a good serviceable edge on the blade. The result is typically “very sharp” with a small secondary bevel and a bit of an “apple seed” profile. The resulting edge is somewhat dependent on the particular blade. Some blades will take and hold sharper edges than others and the thickness of the blade will determine how wide the bevel will need to be. We adjust the angle of the edge to suit the specific blade and attempt to get as close to a bevel-less edge as possible without marring the surface of the blade.

The Sharpening Process

The sharpening service is done with a belt sander. The process involves many passes with sanding belts of various grits. The blades are rested between passes to prevent them from becoming hot and damaging their temper. By default we will sharpen as much of the blade as possible including any false edges if appropriate. If you have a different preference, feel free to make that request in the special instructions at check out. We can sharpen only the last half or third of an edge, for example. Our sword sharpening expert has personally sharpened several thousand swords at this point, so will provide you with a professional service.

What the Service is Not

The resulting edge will be “sword sharp” not razor sharp. Our goal is to provide you with a usable edge for cutting practice that will hold up to some use and not require constant re-sharpening. In other words, we intend to provide you with a serviceable weapon, not a personal grooming implement. The service will not provide a completely bevel-less edge. To create that type of edge will necessarily scratch up the blade surface and we lack the machinery and time to provide a full re-polishing of a blade’s surface. A service of that nature would be significantly more expensive as a great deal more time would be required. We do not offer this type of service at this time.

Disclaimer

We make no guarantee that the resulting edge will meet with your expectations. Every blade is different and some will take and hold a sharper edge than others, due to the blade material, heat treatment or geometry. Some customers can also have incorrect assumptions about sword sharpness and improper expectations as a result. All we can say for sure is that the resulting edge will be sharper than the default edge, in most cases, significantly so. We can not provide any refunds for the service once it has been completed, so consider it to be provided “as is”. That being said, if you are unhappy with the product for any reason, we do still allow you to return the item for a full refund, including the sharpening costs under our normal return policy. This does not apply to special sharpening requests, for example if we sharpen something specially for you that does not normally list that option on our site. The vast majority of our customers are happy with the results of the service, so as long as you keep the above mentioned in mind, we are confident you will be pleased with the results as well.

Greg E. –

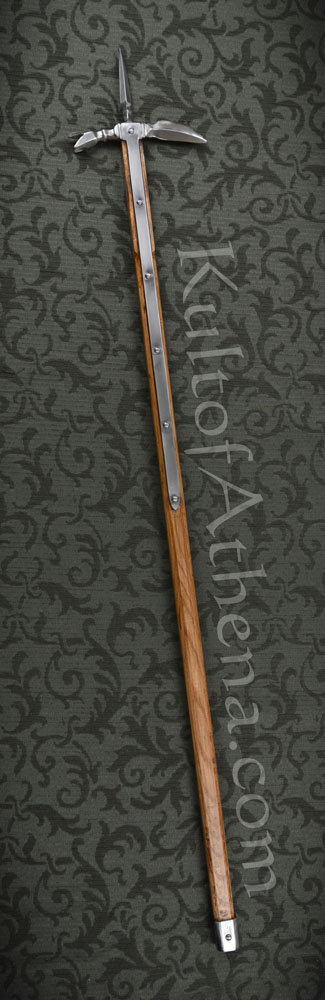

Bec de Faucon Poleaxe by Deepeka The first thing that strikes you about this weapon is it’s size. It seems small in just about every way. It is almost like a 2/3 to 3/4 sized scaled down replica. Very light and a bit short as well. Besides the tips of the hammer, beak and spear being blunted, like after being hit on a really hard surface, it appears to be of decent construction. It comes off as being a toy or a trainer for a 10 year old.

snoweye85 (verified owner) –

finish work was OKAY.

the size, weight is perfect for horseback demonstrations. I was studying its length and cross-referencing to 1390s French knighthood.

i came across the dimensions demands of a certain knight. The size of this polehammer/warhammer is accurate. He wanted it to be no taller than his armpit at standing height. He was able to use it on both horseback and on foot. I plan to add acid etchings and heat-transferring brasswire to different areas to make it a bit more knightly. This is very light and DEVASTING weapon. (RIP pumpkins)

good for price. cons? the finish work was rough, the clawfoot on the hammer end was not even and is cut using angle grinder. I finished off using rod files and multiple sized wood dowels and sandpaper. it now look much neater and presentable. the top spike tip was accidently blunted (dropped?) i sharpened it into prickly sharp. the falcon beak now has razor sharp top and bottom. with sharp drop point. the wood finish on the heft is passable however i added extra layer of linseed oil. it looks darker now. Good buy. this is a good DIY TLC weapon, cricut patterning transfering and acid etching project as well. go for it

Chris (verified owner) –

Seems pretty solid overall, I wish the beak was a little thicker because the tip bent when I hit a coconut, but it still went through with almost no effort and I was able to hammer it back into shape with a single strike so it’s good as new.