Overview

Our sharpening service will provide a good serviceable edge on the blade. The result is typically “very sharp” with a small secondary bevel and a bit of an “apple seed” profile. The resulting edge is somewhat dependent on the particular blade. Some blades will take and hold sharper edges than others and the thickness of the blade will determine how wide the bevel will need to be. We adjust the angle of the edge to suit the specific blade and attempt to get as close to a bevel-less edge as possible without marring the surface of the blade.

The Sharpening Process

The sharpening service is done with a belt sander. The process involves many passes with sanding belts of various grits. The blades are rested between passes to prevent them from becoming hot and damaging their temper. By default we will sharpen as much of the blade as possible including any false edges if appropriate. If you have a different preference, feel free to make that request in the special instructions at check out. We can sharpen only the last half or third of an edge, for example. Our sword sharpening expert has personally sharpened several thousand swords at this point, so will provide you with a professional service.

What the Service is Not

The resulting edge will be “sword sharp” not razor sharp. Our goal is to provide you with a usable edge for cutting practice that will hold up to some use and not require constant re-sharpening. In other words, we intend to provide you with a serviceable weapon, not a personal grooming implement. The service will not provide a completely bevel-less edge. To create that type of edge will necessarily scratch up the blade surface and we lack the machinery and time to provide a full re-polishing of a blade’s surface. A service of that nature would be significantly more expensive as a great deal more time would be required. We do not offer this type of service at this time.

Disclaimer

We make no guarantee that the resulting edge will meet with your expectations. Every blade is different and some will take and hold a sharper edge than others, due to the blade material, heat treatment or geometry. Some customers can also have incorrect assumptions about sword sharpness and improper expectations as a result. All we can say for sure is that the resulting edge will be sharper than the default edge, in most cases, significantly so. We can not provide any refunds for the service once it has been completed, so consider it to be provided “as is”. That being said, if you are unhappy with the product for any reason, we do still allow you to return the item for a full refund, including the sharpening costs under our normal return policy. This does not apply to special sharpening requests, for example if we sharpen something specially for you that does not normally list that option on our site. The vast majority of our customers are happy with the results of the service, so as long as you keep the above mentioned in mind, we are confident you will be pleased with the results as well.

Zidao –

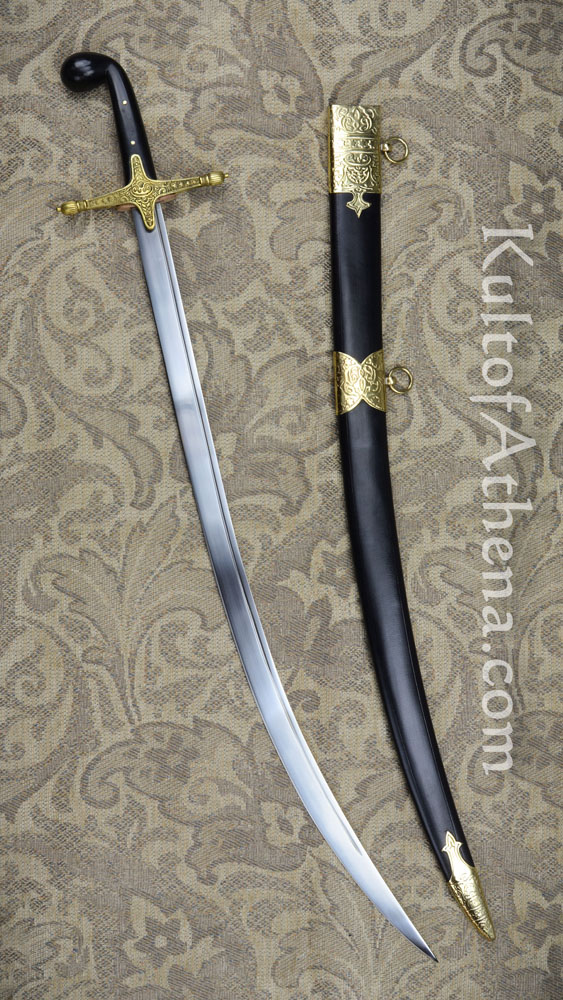

Great Sword at a Good Value The shamshir is a sturdy, well built sword. The curve not only makes it an excellent cutting sword, but allows it to deliver unsuspected hook thrusts. It it light enough to handle well but heavy enough to cut through targets with ease. The sword only took three days to arrive.

William M. –

Quality well built Sword I spent some time looking at different shamshir blades and settled on this. While I’m not too fond of Cold Steel as a company. This sword is surprisingly well made. The fittings are all tight. The grip. While certainly small. Fits well in one hand. It’s a bit slippery due to the polish. I’m not sure what materiel the grip is made out of. But the handle is handle is riveted so it’s sturdy. The brass cross guard is beautiful, Not too fancy but retains the historical cross. The scabbard is also finely made. Quality thick leather is used. It grips the blade but not too much. The brass fittings keep the scabbard in tact. I would have preferred a wood core but for the price it’s nice it comes with one at all. The S curved blade is razor sharp. I did some cut tests and noticed the fuller runs nearly the entire length of the blade. Allowing for quick strikes. The blade has just enough weight to carry the swing for you. It’s rather light in general. The point of balance is 6 inches into the blade making it a bit blade heavy. But seeing as this was a common blade to use while mounted. The point heavy blade means heavier cuts. The best point of contact is 3 inches before the final S curve. At closer inspection. The 1055 blade is actually forged by Windlass. Companies will sometimes do this. They can get a better deal by purchasing blades from other companies and fitting it themselves. I have no complaints though. I actually think Windlass makes some very nice blades. Sharpened this thing is durable and flexible. It bends 60 degrees and bounces back with no effect. Blade geometry is as perfect as ever. My gripe is the handle. The sword will slip and slide around. Forcing you into a hammer grip which gets tiring quickly. The handle is so small that people with large hands will have trouble gripping it. The leather scabbard grips the blade a little to much. Making it awkward to pull out. Other than that it’s great!

Ian S. –

Decent Steel, Sub-par hilt materials TL;DR

Decent steel, cuts well. Faux handle broke during solo drills.

I bought this a few months ago and was enamored with it as it came out of the box. The bend tests results performed by cold steel were included and made me feel I had made a good purchase. I used it only for light cutting and solo drills on air. Never abused it. One day after not having touched it for a few weeks I took it out again to do solo drills and in the middle of a cut (on air) the handle broke at the second rivet. It was then I discovered that this sword has about a 2/3 tang construction, which is my suspicion as to why it broke. I had heard of the bulb on the wooden windlass versions breaking off due to natural grain in the wood, but I assumed this faux horn (some type of plastic) would have been sturdier.

I have no problem with the steel quality. In fact, I still consider this above par among my collection, at least as far as the steel is concerned. Considering I refurbish hilts and handles, this breaking gave me a fun project. I ended up adding a hand guard and almost turning it into a sabre.

In the end I hope i just got a lemon, but I would be cautious recommending this sword, even for the quality steel.

Der L. –

Solid Sword, Sub-Par Scabbard tl;dr – the steel, guard, and handle are all great during cutting and pell work. Brass throat of leather scabbard fell off. Was disappointed with scabbard. Overall, still a good weapon system.

Overview:

I’ve had this sword for years now, and have preformed routine oiling of the blade, and waxing of the leather scabbard. It looks great, and the blade holds a good edge during cutting practice and can handle the shock of impacting a wooden pell.

Pros:

It looks good, feels good, cuts good, and thank the gods for a well fitting scabbard. Definitely one of the better fitting Cold Steel Scabbards in terms of blade retention and ease of draw. It also cones sharp out of the box, which is a huge plus.

Downsides:

The only issue I’ve run into with the system as a whole is the top brass piece on the leather scabbard just decided to take a walk on me. Nothing some contact cement couldn’t fix, but annoying nonetheless.

Frank N Beans –

I purchased this from another site as it was sold out here but it is the current model, The detailing in the guard and pieces on the scabbard make it stand out, the sword itself is very light weight and easy to swing around like nothing. Mine came with a decent edge but I like mine a little sharper the edge is good for cutting but that all depends on how you yourself want the edge. the only thing I didn’t like was how smooth the handle was if knot for the knob it would fly out of the hand, I used grip tape for good grip on mine or you could use some gloves