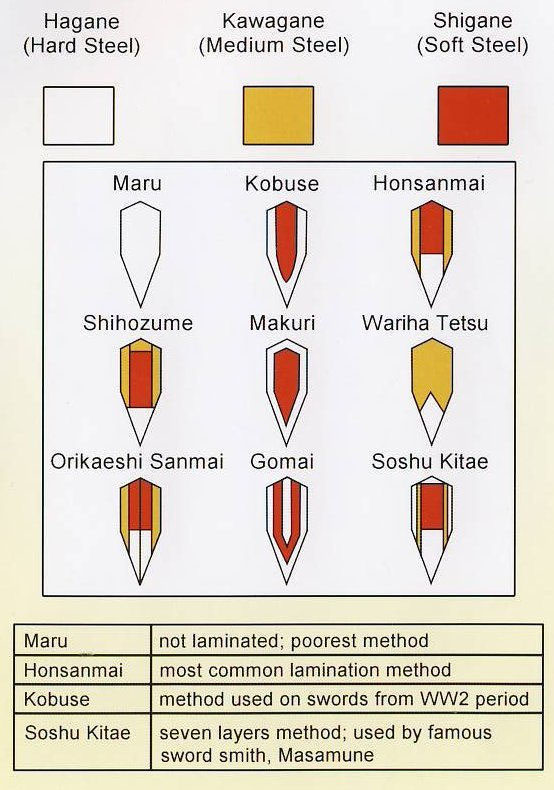

The Unryu Katana is a laminated Katana constructed in the Soshu Kitae method; the blade is a composite of seven forge-welded panels crafted with 1095, 1060 and 1045 high carbon steels. The complex Soshu Kitae method, regarded as the apex of lamination techniques, essentially encapsulates a malleable, shock-absorbing core of steel within a layer of medium-hard steel which is then jacketed in yet harder steel. This final, hard steel layer armors the blade from damage and forms the basis of a keen edge that cuts with decisive finality and resists dulling.

A glance at the edge of the katana reveals the edge lamination line set among a vivid hamon. The hamon was imbued upon the edge when the blade was clad in clay before quenching; This differential-tempering gave the blade a hard, crystalline-steel edge and retained a softer body and spine for durability.

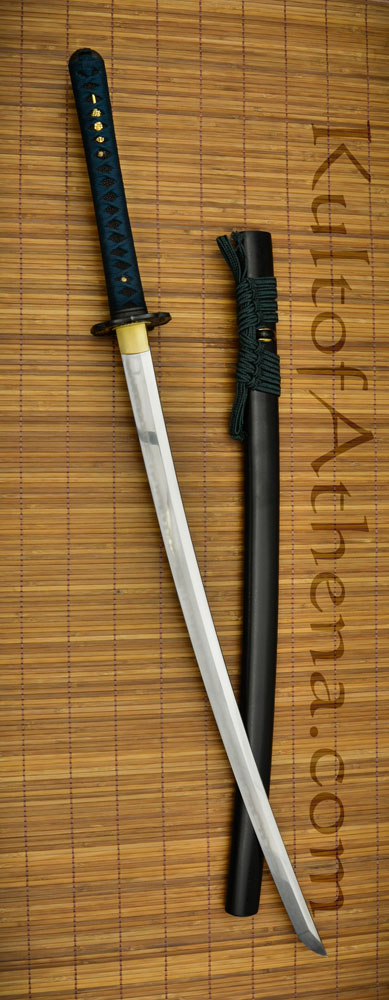

The tip was shaped to form a geometric yokote and an elongated O-Kissaki tip – the spine is left full-bodied and without a bo-hi to retain the full-force cutting capability of the sword. The blade itself was finished with a reflective and fine polish.

The seppa and habaki are brass and the tsuba, kashira and fuchi hilt fittings are iron. The tsuba is emblazoned with a Cloud Dragon highlighted in antiqued brass. The wooden tsuka is inlaid with panels of black lacquered rayskin paired with brass menuki. The tsuka-ito grip wrap is knotted deep green silk; beneath the folds are hishigami inserts to give the grip proper form and to further tighten it. The wood-carved saya scabbard is finalized with a layer of textured black lacquer and a green sageo cord. A cloth sword bag is included.

The Soshu Kitae style is linked by legend to the famous swordsmith Masamune, who perfected this method of forge-welding seven panels of steel with differing properties together into a single blade to give it a hard exterior and a shock-absorbing core.

Japanese blades were often laminated by various methods as a way to position the best type of steel in the best place to optimize the sword overall. As an added benefit it made the blade durable by not only giving it a tough spine, but should a panel be damaged then it would be more likely that the damage would be restricted to a single panel, thereby simply damaging a blade, instead of crippling it when its wielder likely was in the greatest hour of need for a sound blade to see the duel or battle through.

The wide availability of high-quality pure steel and modern aids to tempering have made swords of simpler structural design quite efficient and performance equals of laminates without the drawback of composite welds; a reality that could not exist in feudal Japan. Yet the allure of laminated Katana is to the collector and the enthusiast who desires a sword forged with these authentic and painstaking processes; a sword that is a display of the traditional, yet practical artistry of craftsmen who by way of skill and sure will formed immaculate weapons from stubborn natural materials. Their dedication to their craft created the powerfully functional artistry that is the Katana.

Arthur C (verified owner) –

Wow exactly what is shown on the pictures… came in the mail today. Delivered to Wisconsin same day it was shipped from Illinois. Delivery was super fast. The blade is fully coated with oil to preserve it. Would be nice if it had a bo-hi on it to maintain weight however more cutting power will increase without it.

Would buy again:)

karatekidd.ep (verified owner) –

This sword is great piece! The only downside was the saya was a tad loose but other than that, this is a solid sword for the price