Overview

Our sharpening service will provide a good serviceable edge on the blade. The result is typically “very sharp” with a small secondary bevel and a bit of an “apple seed” profile. The resulting edge is somewhat dependent on the particular blade. Some blades will take and hold sharper edges than others and the thickness of the blade will determine how wide the bevel will need to be. We adjust the angle of the edge to suit the specific blade and attempt to get as close to a bevel-less edge as possible without marring the surface of the blade.

The Sharpening Process

The sharpening service is done with a belt sander. The process involves many passes with sanding belts of various grits. The blades are rested between passes to prevent them from becoming hot and damaging their temper. By default we will sharpen as much of the blade as possible including any false edges if appropriate. If you have a different preference, feel free to make that request in the special instructions at check out. We can sharpen only the last half or third of an edge, for example. Our sword sharpening expert has personally sharpened several thousand swords at this point, so will provide you with a professional service.

What the Service is Not

The resulting edge will be “sword sharp” not razor sharp. Our goal is to provide you with a usable edge for cutting practice that will hold up to some use and not require constant re-sharpening. In other words, we intend to provide you with a serviceable weapon, not a personal grooming implement. The service will not provide a completely bevel-less edge. To create that type of edge will necessarily scratch up the blade surface and we lack the machinery and time to provide a full re-polishing of a blade’s surface. A service of that nature would be significantly more expensive as a great deal more time would be required. We do not offer this type of service at this time.

Disclaimer

We make no guarantee that the resulting edge will meet with your expectations. Every blade is different and some will take and hold a sharper edge than others, due to the blade material, heat treatment or geometry. Some customers can also have incorrect assumptions about sword sharpness and improper expectations as a result. All we can say for sure is that the resulting edge will be sharper than the default edge, in most cases, significantly so. We can not provide any refunds for the service once it has been completed, so consider it to be provided “as is”. That being said, if you are unhappy with the product for any reason, we do still allow you to return the item for a full refund, including the sharpening costs under our normal return policy. This does not apply to special sharpening requests, for example if we sharpen something specially for you that does not normally list that option on our site. The vast majority of our customers are happy with the results of the service, so as long as you keep the above mentioned in mind, we are confident you will be pleased with the results as well.

TSI (verified owner) –

This thing is wicked sharp and solid built from what I can tell. Cut through a ton of water bottles today and this thing puts back yard cutting on easy mode!

John (verified owner) –

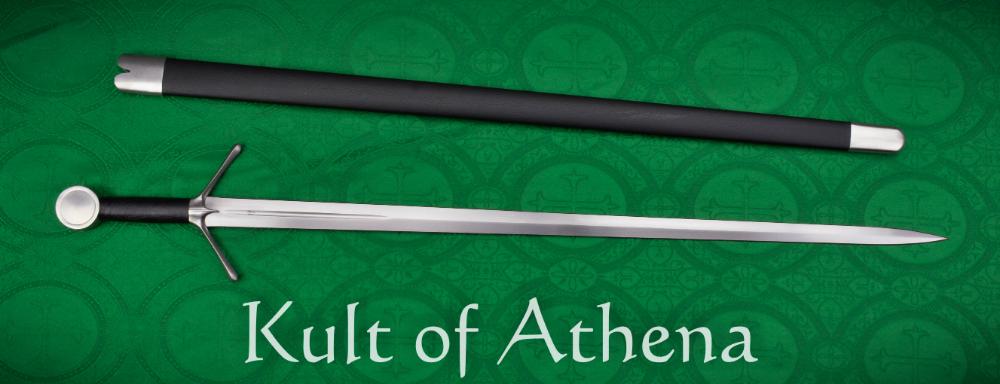

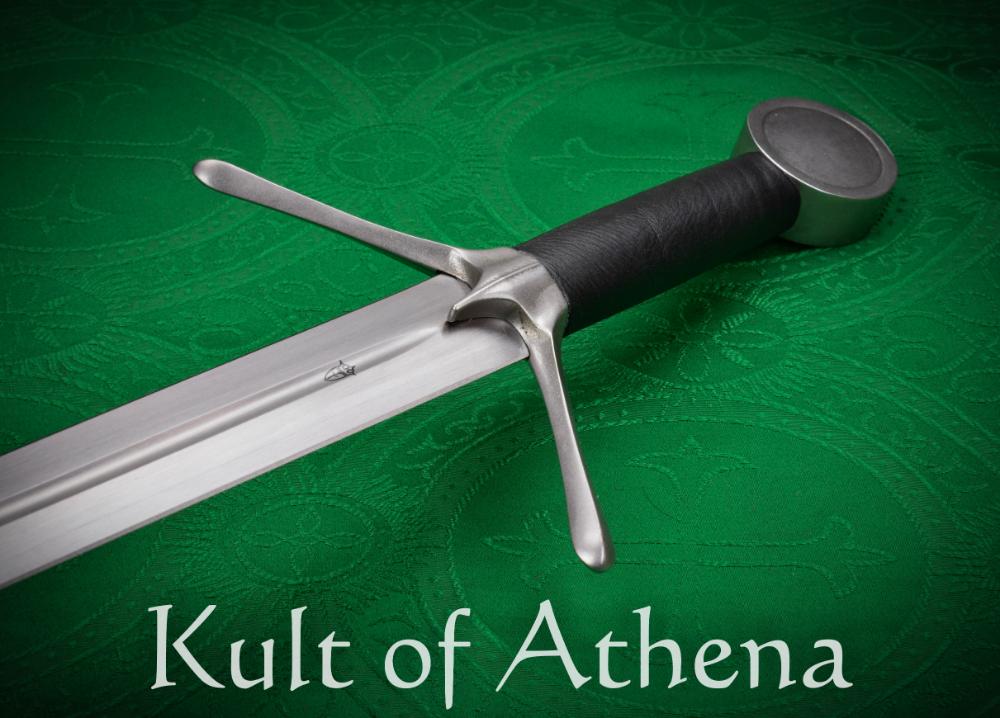

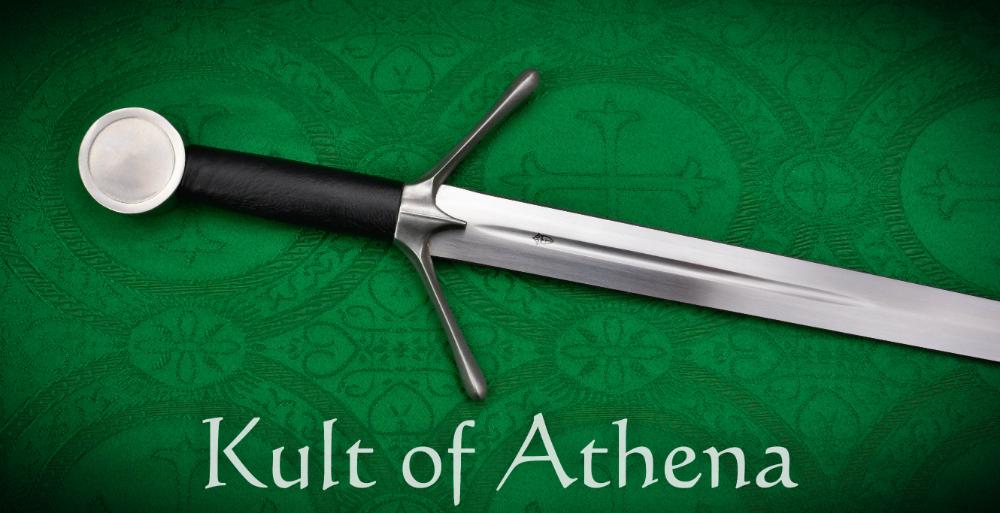

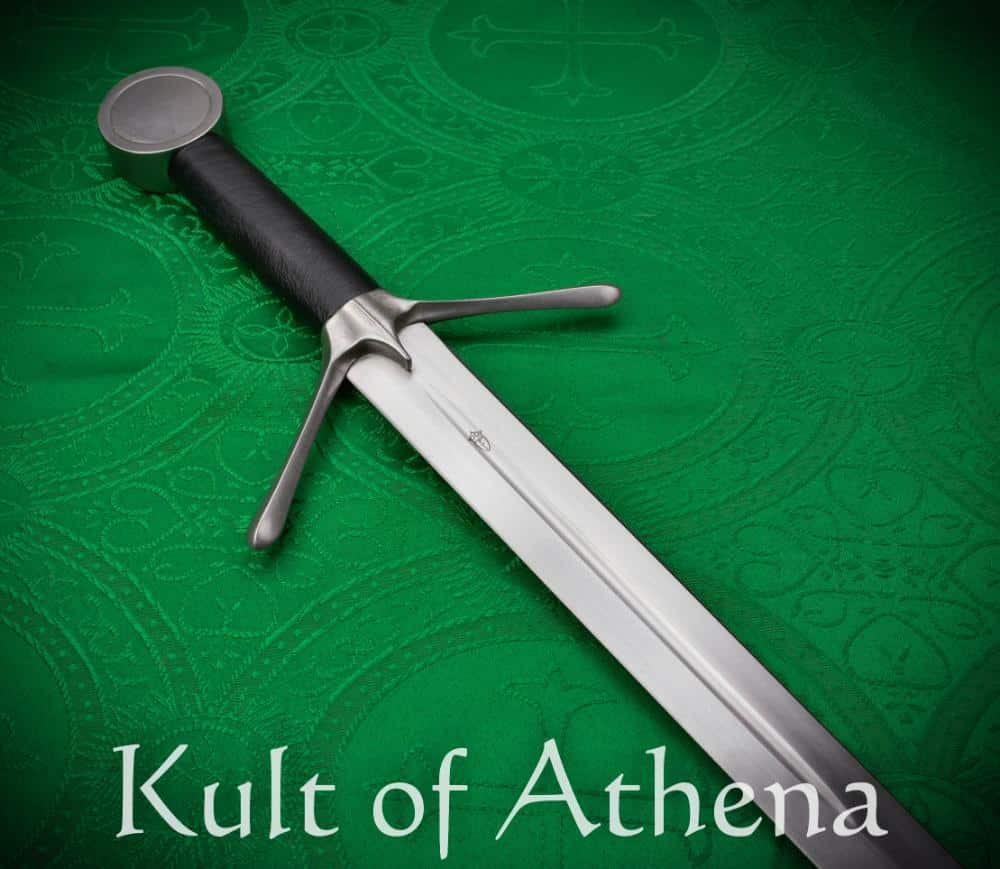

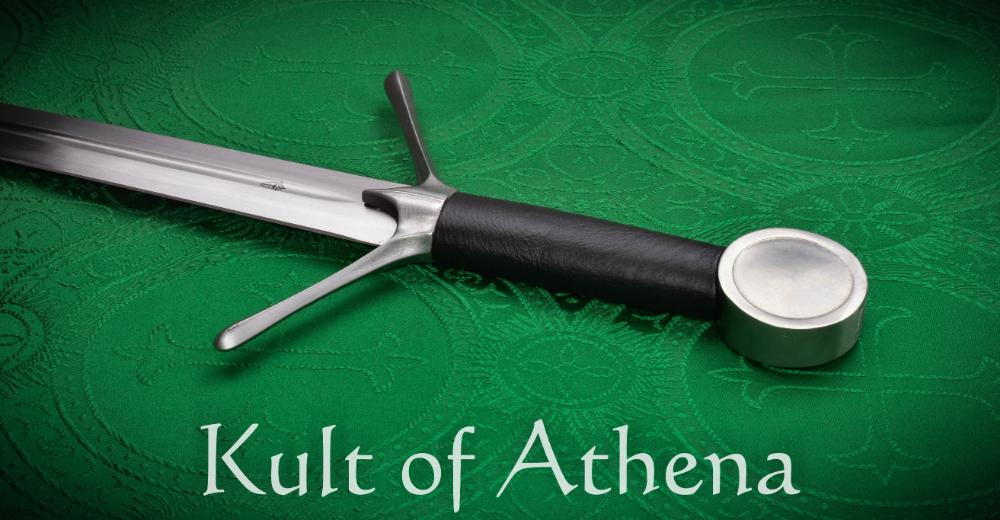

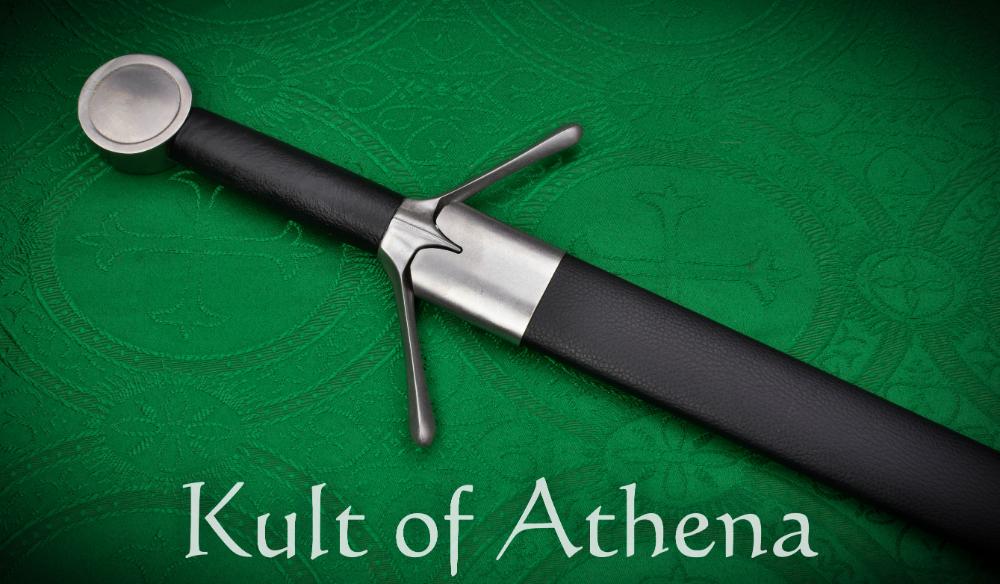

There are a couple of details that I am wondering about. The pommel is interesting, having a taper from the grip to the peened, square end of the tang. The original swords are typified by a hollow pommel. Short of dismantling the grip, or damaging the pommel, it isn’t clear how the pommel is constructed. That said the fit and finish of the pommel short signs of slightly inaccurate blow placement when the end of the tang was peened. Face of the pommel is recessed from the outer edge about 5 mm in from the actual side of the pommel. The face itself is slightly domed, and the join between the recessed face and the rim shows small details that could the result of the pommel being cast.

The quillons look very like originals on at least one original example, and again have small trace marks that indicate they may be cast.

The grip is supposed to be leather over wood, and may very well be, but there is no stitched seam. The covering appears to be glued on.

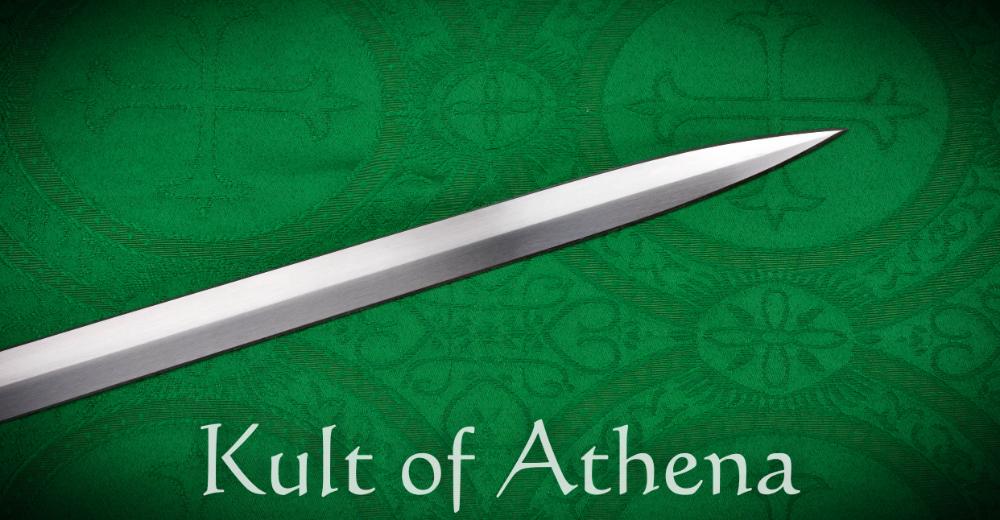

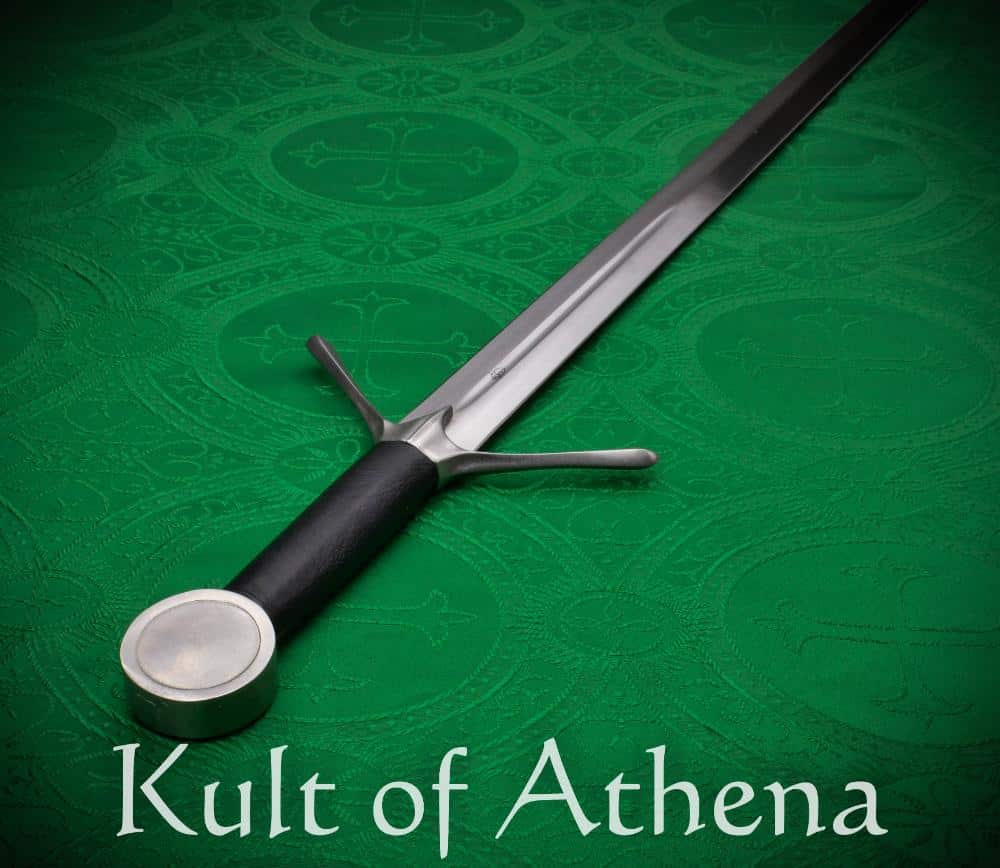

The blade is nicely made, with a clear mid-rib, POB is 14.5 cm and POC is about 51 cm. The fullers are short – 17.cm long and start about 5 mm beyond the ends of languettes.

It’s light, handy, and fairly serious in a cut.

jeffreynickels2021 (verified owner) –

Scabbard is tighter around the throat then I’d prefer but the sword is light and very well balanced. Amazing sword.