Overview

Our sharpening service will provide a good serviceable edge on the blade. The result is typically “very sharp” with a small secondary bevel and a bit of an “apple seed” profile. The resulting edge is somewhat dependent on the particular blade. Some blades will take and hold sharper edges than others and the thickness of the blade will determine how wide the bevel will need to be. We adjust the angle of the edge to suit the specific blade and attempt to get as close to a bevel-less edge as possible without marring the surface of the blade.

The Sharpening Process

The sharpening service is done with a belt sander. The process involves many passes with sanding belts of various grits. The blades are rested between passes to prevent them from becoming hot and damaging their temper. By default we will sharpen as much of the blade as possible including any false edges if appropriate. If you have a different preference, feel free to make that request in the special instructions at check out. We can sharpen only the last half or third of an edge, for example. Our sword sharpening expert has personally sharpened several thousand swords at this point, so will provide you with a professional service.

What the Service is Not

The resulting edge will be “sword sharp” not razor sharp. Our goal is to provide you with a usable edge for cutting practice that will hold up to some use and not require constant re-sharpening. In other words, we intend to provide you with a serviceable weapon, not a personal grooming implement. The service will not provide a completely bevel-less edge. To create that type of edge will necessarily scratch up the blade surface and we lack the machinery and time to provide a full re-polishing of a blade’s surface. A service of that nature would be significantly more expensive as a great deal more time would be required. We do not offer this type of service at this time.

Disclaimer

We make no guarantee that the resulting edge will meet with your expectations. Every blade is different and some will take and hold a sharper edge than others, due to the blade material, heat treatment or geometry. Some customers can also have incorrect assumptions about sword sharpness and improper expectations as a result. All we can say for sure is that the resulting edge will be sharper than the default edge, in most cases, significantly so. We can not provide any refunds for the service once it has been completed, so consider it to be provided “as is”. That being said, if you are unhappy with the product for any reason, we do still allow you to return the item for a full refund, including the sharpening costs under our normal return policy. This does not apply to special sharpening requests, for example if we sharpen something specially for you that does not normally list that option on our site. The vast majority of our customers are happy with the results of the service, so as long as you keep the above mentioned in mind, we are confident you will be pleased with the results as well.

Andy –

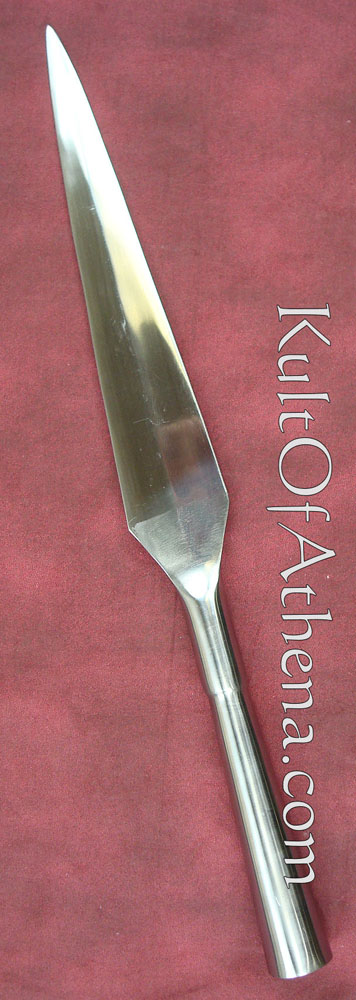

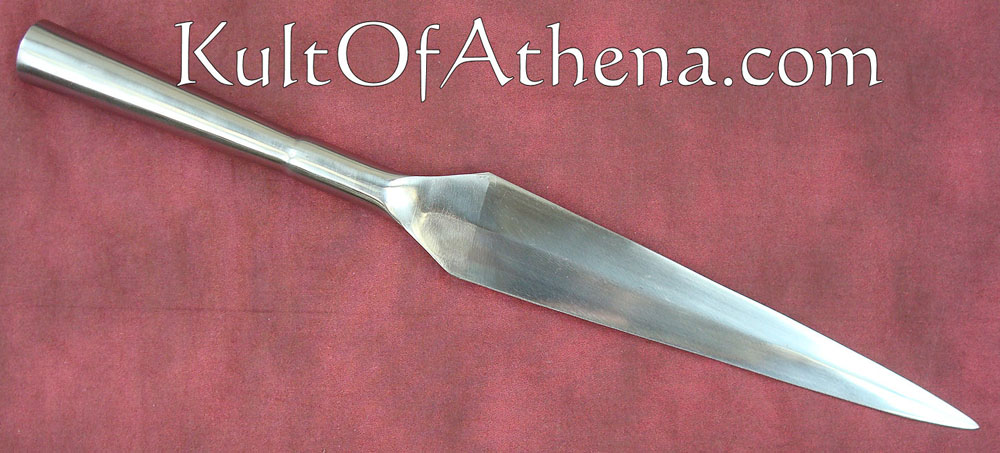

Could not be happier I am going to making a short hewing spear with this, and I think it is perfect for that purpose. The socket is reinforced right in the spot where these big spearheads always break, so that is a big plus in my book.

DPS –

Battle Ready is not Stage Ready I knew going in that Battle Ready does not mean Stage Combat worthy. I’ve had 2 break in a single show. They seemed thick enough, but the metal really isn’t strong enough to withstand stage use. (Note- After the first cracked, I actually was able to bend back and forth until it tore apart with just my hands). They do have a good basic look though, and I will keep the rest for set dressing and non-fight use.

Nathan –

Dimensions not accurate Point is sharp, nice exterior finish…only problem, the socket diameter is 1 3/16, not 1 3/8. I purchased the pole I intended to use as a spearshaft based on the advertised dimension…now I have to go get another one. Not a huge problem, just annoying.

The good news is that, while the pictures seem to show only one nailhole for securing the head to the shaft, there are actually two, and the are properly offset for stability.

Charles V. DeLeo (verified owner) –

The overall design looks astonishing! It fits perfectly to the staff that I have for it. The only problem is that the pre-drilled holes for securing the pin are offset. They don’t line up with one another, so I’m concerned that could cause the spear to break with one wrong move. Apart from that, it looks spectacular.